Equipment and components that Predictive Maintenance NDT Inc. frequently performs PT and/or FPI on include, but are not limited to…

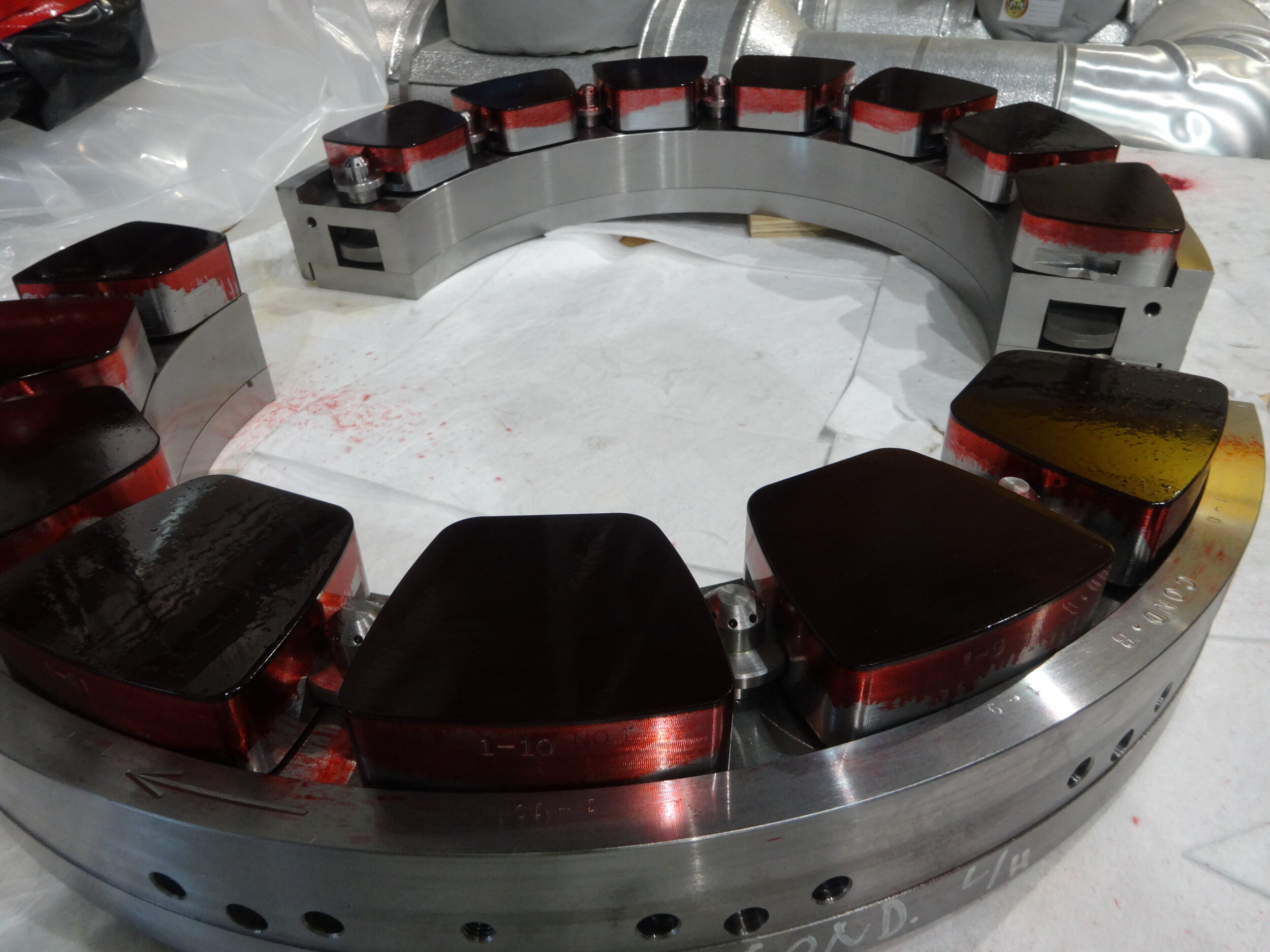

Gas Turbine Rotating Equipment

Gas Turbine Combustion Components

Heat Recovery Steam Generator and Boiler Components

Steam Turbine Rotating Equipment

Generator Rotors and Fan Blades

Bearings, Bearing Journals, and Bearing Parts

Valves and Valve Parts

Pumps and Pump Parts

Field and Factory Welds

Pre-Fabrication and Fabrication Components

Nonferrous Metals, Alloys, and Ceramics

And Many More

Tap below for more detailed information on our penetrant inspection services.

Liquid Penetrant Testing

Liquid Penetrant Inspection (PT): A variety of specialty solutions are used in this process to detect surface discontinuities. The sensitivity of the inspection can be adjusted to fit the application, making PT a well-suited inspection method for the discovery of discontinuities by magnifying their size and location.

Fluorescent Penetrant Inspection

Fluorescent Penetrant Inspection (FPI): Solutions with the same properties as the visible liquid penetrant are used in FPI, only with fluorescent dye agents. It’s high sensitivity and contrast with the use of ultraviolet lighting, make FPI a successful process for detecting very small surface discontinuities.